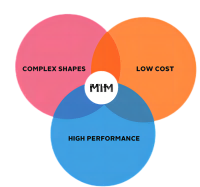

Advantages of Metal Injection Molding

The main advantages of the MIM process are:

Complex Geometries

Cost-Effectiveness

Consistent Quality

Material Selection

Density & Strength

1.Complex Geometries

MIM parts can be made with intricate internal structures, thin walls, and complex shapes, making it possible to produce functional and aesthetically pleasing components. In addition to complex geometries, MIM also offers tight tolerances, which is important for ensuring the proper fit and function of the component.

2. Cost-Effectiveness

Metal injection molding is considered cost-effective due to several reasons, including reduced labor and reduced waste.

MIM is a highly automated process, which reduces the need for manual labor, compared to traditional metal forming methods. This can result in significant labor savings, especially for high-volume production runs.

The metal injection molding process also generates very little scrap, which reduces the amount of discarded material and the associated costs. The high precision of MIM reduces the need for secondary operations, such as finishing and assembly, which can also result in cost savings.

3. Consistent Quality

Consistent quality is achieved in metal injection molding for the following reasons:

Repeatability

The MIM process is highly automated and repeatable, which ensures that each part produced is exactly the same. This reduces the risk of defects and ensures the parts meet specified design and tolerance requirements.

Consistent Raw Material Quality

The MIM process starts with the creation of a metal powder that’s mixed with a binding material to form a feedstock. Metal powders used in the MIM process are highly consistent in composition and particle size, which reduces variability in the final parts and ensures consistent quality.

Controlled Environment

Metal injection molding takes place in a controlled environment, reducing the risk of contamination and defects. The high pressure and heat used in the process also eliminate any porosity or inclusions that might be present in the feedstock, ensuring the final parts are of high quality.

4. Material Selection

A wide range of material options are available with metal injection molding, including stainless steel, titanium, and low-alloy steels. This gives engineers the flexibility to choose the best material for their specific application.

5. Density & Strength

MIM parts are produced with a high degree of density, which results in excellent mechanical properties, including strength and hardness. This makes MIM a great solution for components that need to withstand high stress and wear.